The U.S. Army Corps of Engineers (USACE) had developed a preliminary design for the largest adult fish trap & haul facility in the country. However, they were applying standard fish trap technology involving vertical lifts and holding for manual sorting, which was being overwhelmed in the operational model by the number of fish they were trying to handle (up to 60,000 adult fish per day).

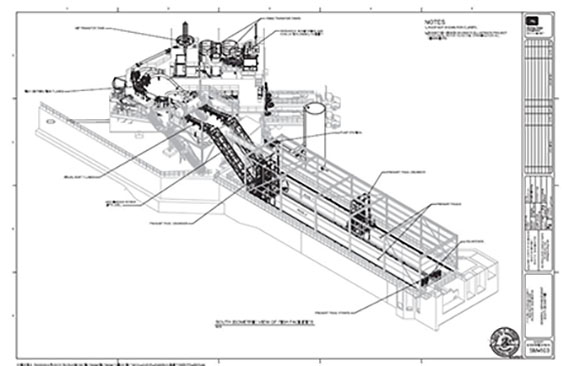

Kleinschmidt proposed an unprecedented solution involving Archimedes screw lifts (ASLs) and flumes leading to transport trucks or a sampling facility and then negotiated acceptance of it with the National Marine Fisheries Service (NMFS). The solution allows continuous fish movement from presort pools to the fish transport trucks while visually identifying and sorting fish without stopping them. Therefore, there are no traps, lifts, or intermediate pools to get overloaded.

The continuous lifting and passing of fish directly to the transport trucks, while visually sorting the fish in motion, allowed the USACE to construct a trap & haul facility that can sort and transport up to 60,000 adult salmon in 24 hours with a reduced number of people required as compared to traditional manual handling and sorting of each fish. Our team also assisted the USACE with engineering support during project construction, providing real-time answers to questions that could have increased construction costs or delays if not addressed promptly.

Regional Vice President

Paul Larson, P.E.

Paul Larson has 28 years of hydropower and infrastructure experience and is Kleinschmidt’s Northwest Regional Vice President. and specializes in the management of technical teams relative to engineering and utility operations. Paul has managed cross-disciplinary teams on a wide range of hydropower generation, transmission, and distribution projects and other projects for clients in the Northwest....